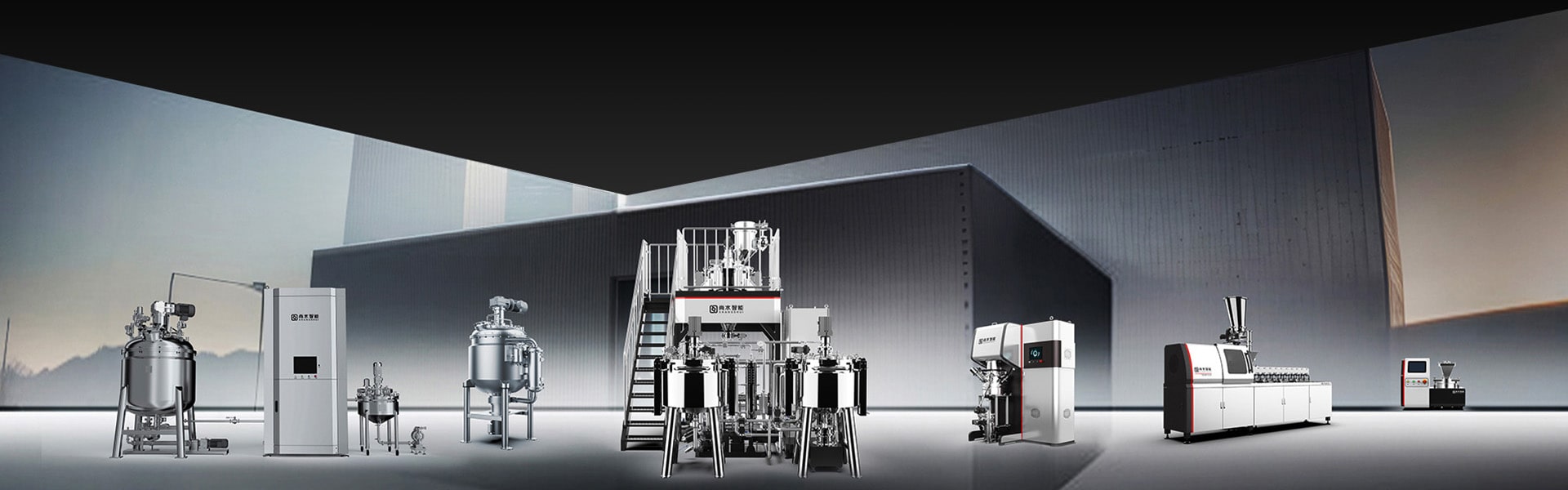

Extensively used in new energy, coatings, cosmetics, food, and pharmaceutical industries. The new vertical medium grinding system utilizes large-size grinding media for coarse grinding, effectively breaking up agglomerates in the initial stage of high-viscosity slurry grinding. Fine grinding employs smaller grinding media, and a special rotor structure design enhances fine grinding efficiency. This system is especially suitable for grinding and dispersion of carbon nanotube slurry.

Extensively used in new energy, coatings, cosmetics, food, and pharmaceutical industries.

The new vertical medium grinding system utilizes large-size grinding media for coarse grinding, effectively breaking up agglomerates in the initial stage of high-viscosity slurry grinding. Fine grinding employs smaller grinding media, and a special rotor structure design enhances fine grinding efficiency. This system is especially suitable for grinding and dispersion of carbon nanotube slurry.

Slurry enters the grinding chamber from the bottom inlet and mixes with the grinding media in the rotating rotor. Solid particles in the slurry disperse and de-agglomerate under the collision, friction, and shearing action of the grinding media, quickly reducing slurry viscosity and fineness. The ground slurry discharges through the outlet screen and outlet.