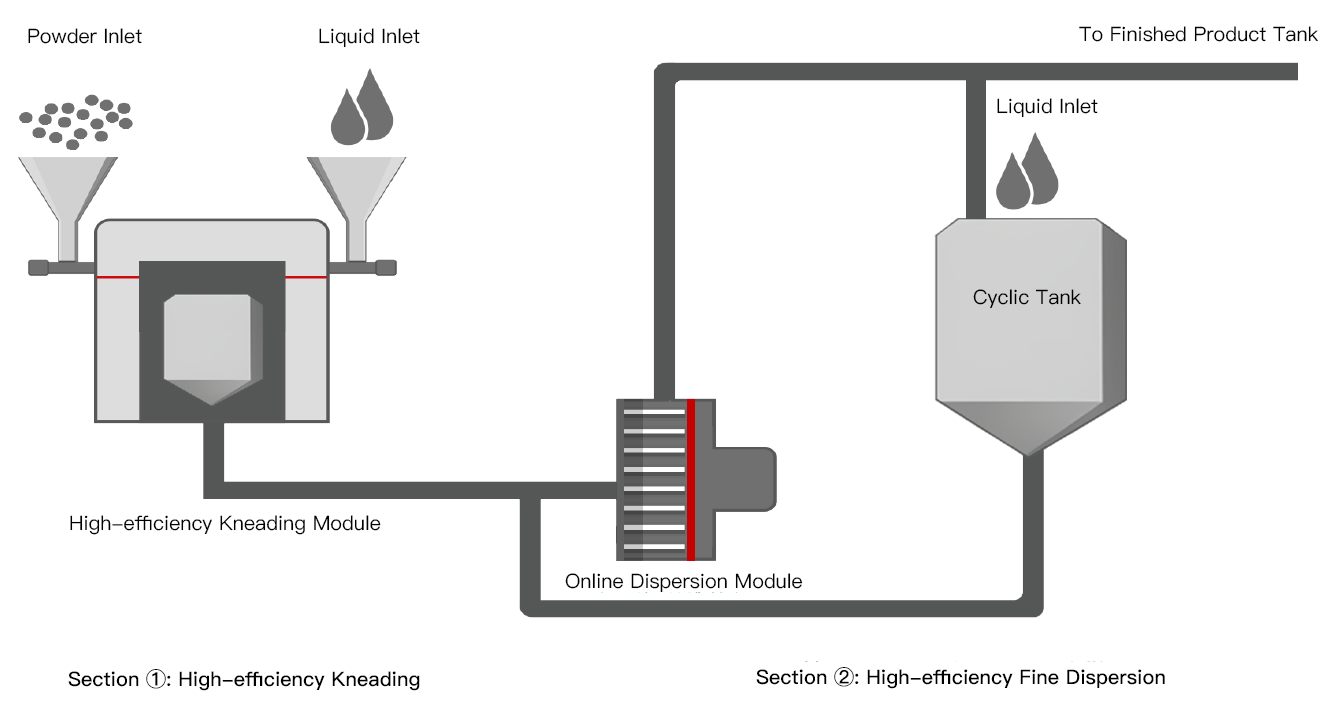

Significantly Improve Kneading Dilution Efficiency

The high-speed rotor generates the primary kneading force, while the low-speed paddle with an opposite rotation direction interacts to keep materials continuously working in the high-speed kneading zone. Kneading time is reduced to just 1/4-1/3 of that required by traditional mixers. The opposite rotation shearing mechanism also greatly enhances dilution efficiency compared with mixers.

Dead-Angle-Free Kneading Dilution

The low-speed paddle covers all material areas in the tank, ensuring full participation in kneading. An efficient spray system at the top cleans the agitating paddle and powder adhering to the tank cover, accurately maintaining the slurry formulation ratio.

Reliable and Simple Structure

Compared to traditional stirring and kneading processes, this design is simplified, easy to maintain, and has low usage costs.

Laboratory Type

Laboratory Type Small/Medium Test Type

Small/Medium Test Type Mass Production Type

Mass Production Type