It is extensively employed in industries such as lithium-ion battery materials, ceramics, minerals, ceramic inks, coatings, food, beverages, pharmaceuticals, and cosmetics. It is particularly effective for pulverizing crystalline materials like sodium and lithium salts.

It is extensively employed in industries such as lithium-ion battery materials, ceramics, minerals, ceramic inks, coatings, food, beverages, pharmaceuticals, and cosmetics. It is particularly effective for pulverizing crystalline materials like sodium and lithium salts.

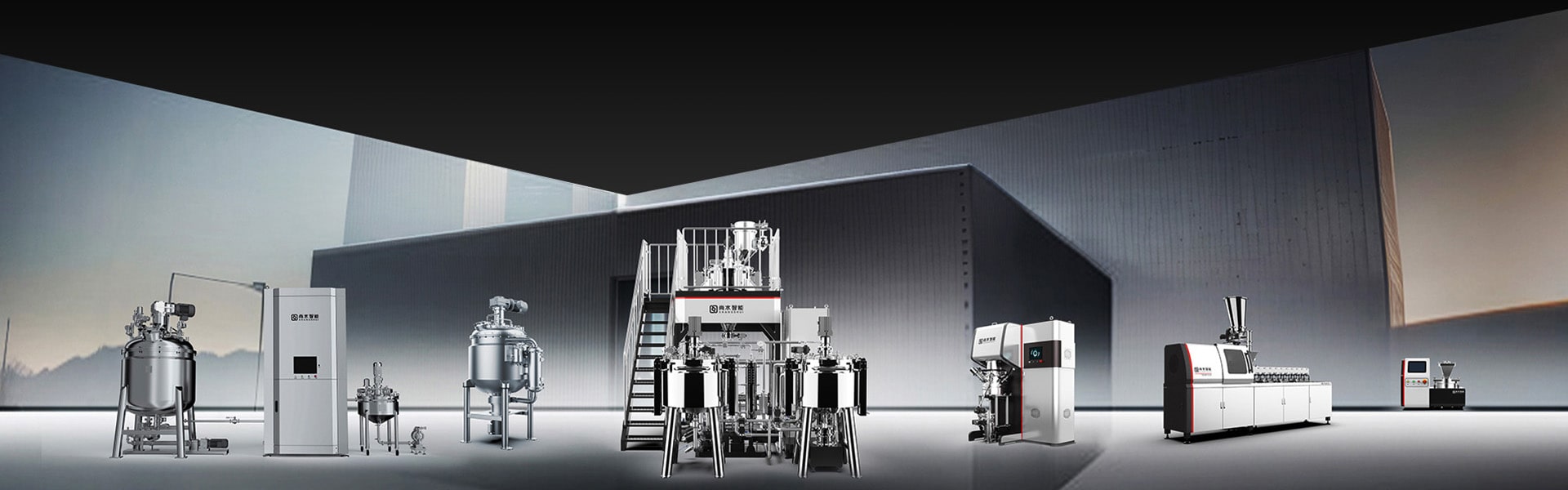

The equipment features a discharge device that uniformly feeds materials from the inlet into the grinding chamber, where grinding media are agitated by a rotor, resulting in friction and impact to crush the materials. A spiral pusher paddle near the discharge outlet propels the material toward the exit, enabling continuous production. Simulation technology optimizes the equipment structure, enhancing the probability of effective media collisions and significantly improving production capacity.