Widely used in new energy, coatings, cosmetics, food, pharmaceutical, and other industries. The technology is especially suitable for surface coating modification of power lithium-ion battery cathode and anode materials, efficiently and uniformly coating active material particle surfaces, and significantly improving electrode material performance.

Widely used in new energy, coatings, cosmetics, food, pharmaceutical, and other industries. The technology is especially suitable for surface coating modification of power lithium-ion battery cathode and anode materials, efficiently and uniformly coating active material particle surfaces, and significantly improving electrode material performance.

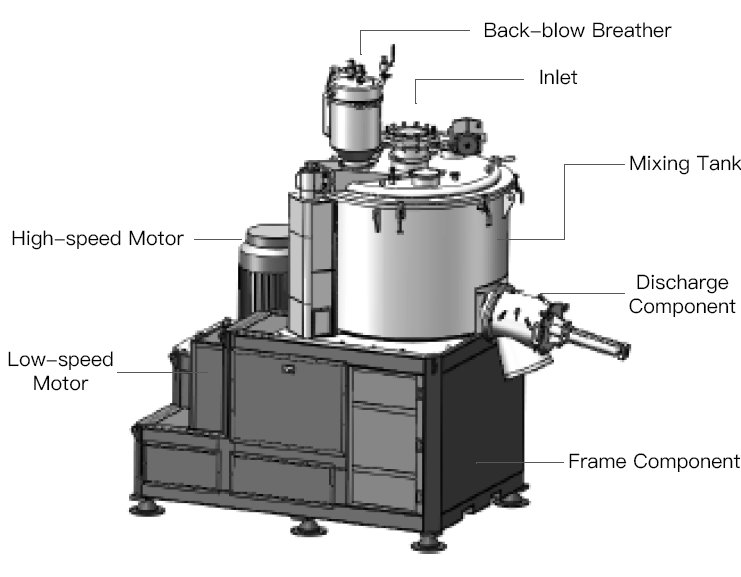

During the materials’ upward and downward movement, the opposite rotation direction and varying speed of the low-speed paddle and high-speed paddle generate strong convection mixing. Simultaneously, paddle stirring causes a speed difference between materials, enhancing the shearing and mixing effect, allowing for even dispersion and mixing in a short time.