Suitable for the lithium-ion battery industry (e.g., alumina slurry, battery positive and negative electrode slurry), as well as coatings, inks, food, beverages, pharmaceuticals, cosmetics, and other industries. Ideal for dispersing temperature-sensitive, shear-sensitive slurry, as well as high-viscosity, hard-to-pump suspensions.

Suitable for the lithium-ion battery industry (e.g., alumina slurry, battery positive and negative electrode slurry), as well as coatings, inks, food, beverages, pharmaceuticals, cosmetics, and other industries. Ideal for dispersing temperature-sensitive, shear-sensitive slurry, as well as high-viscosity, hard-to-pump suspensions.

Compared with traditional mixers, taking a 1200L/h slurry mixing system as an example

| Items | Cyclic High-efficiency Slurry Mixing Machine | Planetary Mixer Slurry Mixing | Remarks |

|---|---|---|---|

| Capacity | 1200 L/h | 1200 L/h | |

| Equipment Configuration | 1200L Cyclic High-speed Slurry Machine×1 2000L Cyclic Tank×2 600L Twin Screw Pump×1 | 1200L Planetary Mixer×3 1200L Buffer Tank×1 Pneumatic Diaphragm Pump×1 | Cyclic High-speed Slurry Machine can produce 1800L slurry per batch (1.5h) Planetary Mixer can produce 1300L slurry per batch (3h) |

| Installed Power | 205 kW | 462 kW | |

| Unit Energy Consumption | 50 kWh/t | 220 kWh/t | Saving 215 kWh per ton of slurry |

| Floor Area | 6 m×4.5 m | 18 m×7.5 m | Floor Area Savings 408m² |

| Number of Shift Workers | 1 person/shift | 3 person/shift | Saving 2 people per shift |

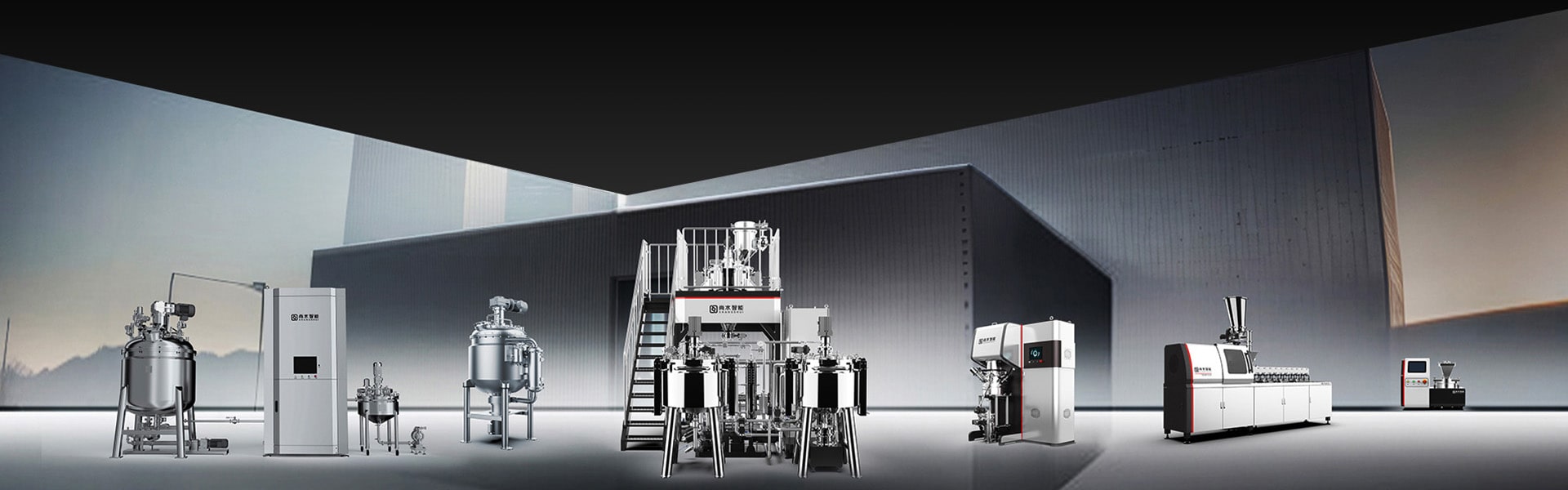

In contrast to traditional double planetary mixers with low capacity, high energy consumption, multiple required systems, high equipment investment cost, high labor cost, and large factory space requirements, the cyclic high-speed slurry machine overcomes capacity limitations. A single machine achieves larger capacity with a small size, high efficiency, low unit energy consumption, and great equipment investment and labor costs.