Shangshui Process Route

Key Advantages

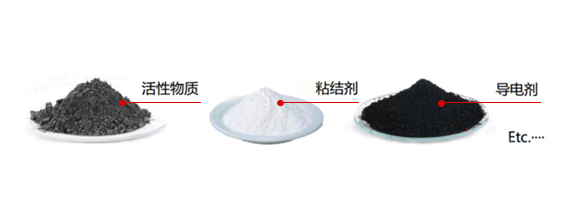

Widely Applicable: Suitable for material mixing, coating, drying, crushing, dry electrode processes, and more.

High-Speed Shearing: Maximum linear speed up to 60 m/s.

Precise Temperature Control: Cylinder temperature control with an accuracy of ±5℃ and a range of -30℃ to 300℃.

Customized Simulation Design: Impeller blades are designed via simulation for different materials to ensure uniform mixing.

Low PTFE & Additive Content: < 2%

Low-Temperature, High-Speed Mixing: Process temperature maintained below 19°C

Batch Mixing Time: 30 to 40 minutes per batch

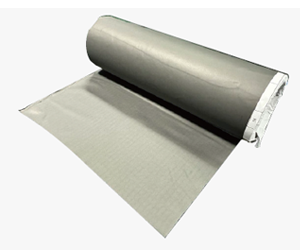

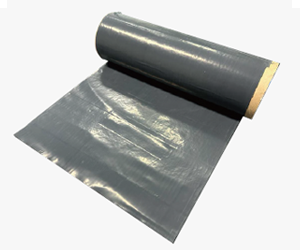

PTFE Low-Temperature Coating

Process temperature < 19°C, enabling PTFE to form a thin-film coating on particle surfaces. This reduces the difficulty of PTFE fibrillation and significantly improves fibrillation consistency.

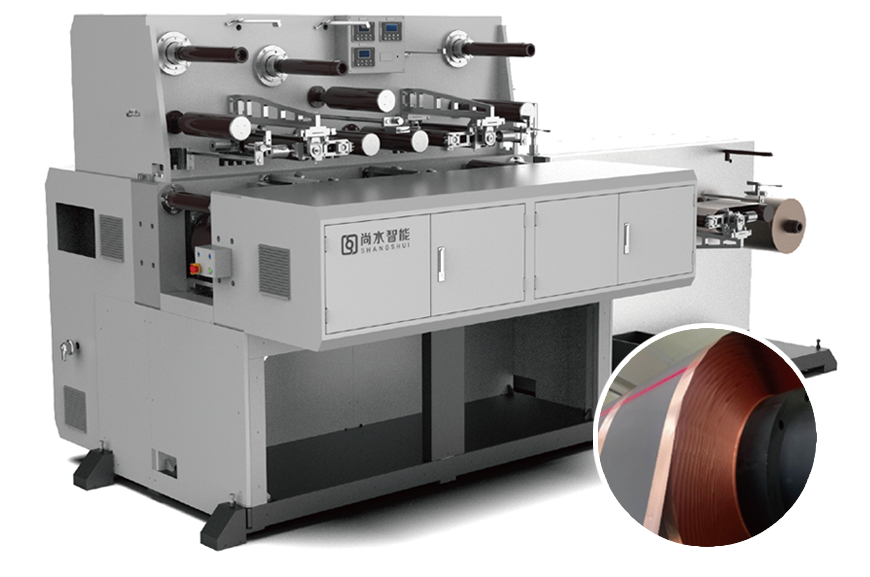

Dual-Drive Coating Machine

Product Specifications & Technical Parameters

Product Specifications & Technical Parameters

| 设备型号 | PB-2 | PB-10 | PB-30 | PB-100 | PB-300 | PB-600 | PB-1000 | PB-2000 |

|---|---|---|---|---|---|---|---|---|

| 简体容积(L) | 2 | 10 | 30 | 100 | 300 | 600 | 1000 | 2000 |

| 最大填充量(L) | 0.8 | 0.5 | 18 | 60 | 180 | 360 | 700 | 1400 |

| 高速电机功率(KW) | 0.75 | 5 | 10 | 37 | 75 | 90 | 100 | 110 |

| 高速浆叶转速(rpm) | 8000 | 5000 | 3000 | 1000 | 800 | 700 | 600 | 600 |

| 设备重量(kg) | 50 | 450 | 500 | 900 | 1500 | 2400 | 4500 | 9500 |

Key Advantages

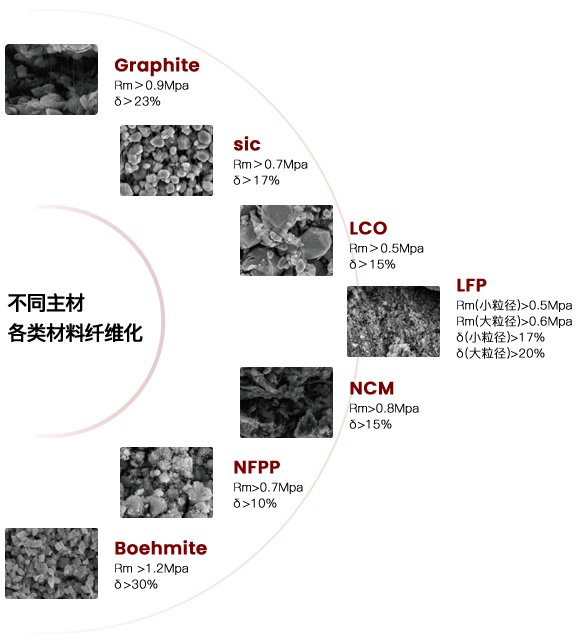

Flexible Screw Configuration & Process Adaptability: Threaded elements can be flexibly arranged for strong process compatibility.

Controlled Fibrillation via Stable Flow: Consistent material flow and uniform particle residence time enable precise fibrillation control.

Independent Sectional Temperature Control: Features independently controlled temperature zones with an accuracy of ±5°C, capable of both cooling and heating.

Short Process Time & High Efficiency: Achieves high efficiency with a reduced processing cycle.

Integrated Fibrillation & Granulation: Combines the fibrillation and granulation steps into one continuous process.

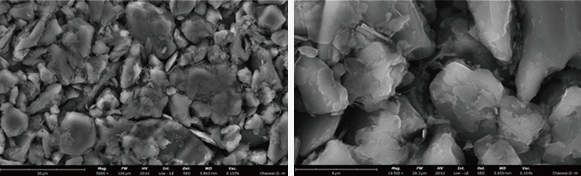

Universal Material Fibrillation: Capable of processing a wide range of materials with precise fibrillation degree control from 0% to 100%.

High Production Capacity: Output exceeds >140 kg/h for graphite and >450 kg/h for NCM.

Integrated Fibrillation & Granulation: Combines fibrillation and granulation in one step, with freely controllable particle sizes ranging from 0.1 to 1 mm.

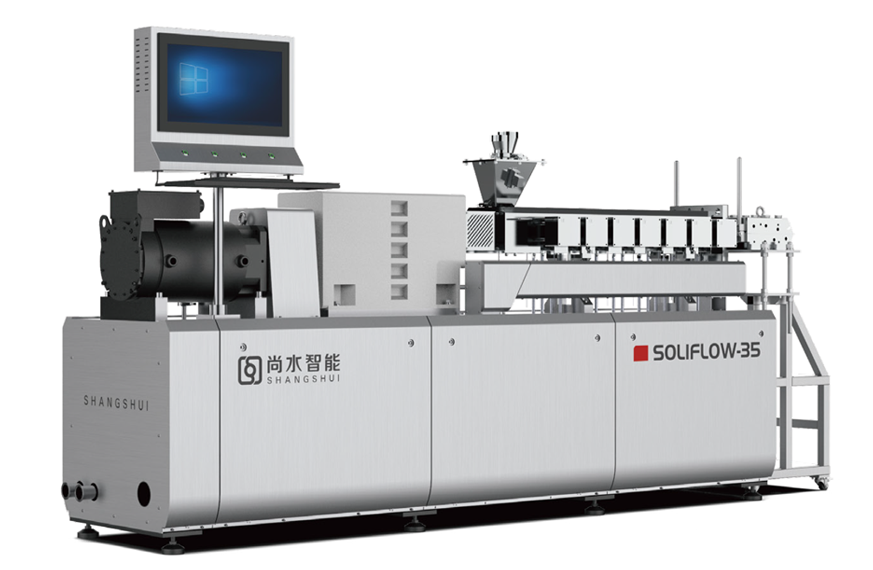

Twin-Screw Extruder

| 型号 | SF-35 |

|---|---|

| 螺杆外径 | 35.6mm |

| 转速 | 0~1000rpm |

| 线速度 | 0~1.86m/s |

| 温控范围 | 10℃~300℃ |

Graphite

Lithium Iron Phosphate (LFP)

Integrated Calendering & Lamination Machine

| 型号 | MC3035 |

|---|---|

| 轧辊尺寸 | Φ300x350mm |

| 有效宽度 | 300mm |

| 线速度 | 50m/min |

| 温控范围 | 25℃~200℃ |

| 压力 | 100T |